- Home

- Metering System

Manufacturer of eXcellent measurement packages

EXIMP international has extensive experience as a specialized engineering contractor for design, fabrication and commissioning of flow measurement packages for worldwide Oil & Gas industry.

As an independent integrated solutions provider, EXIMP objectively analyses the various metering technologies available and selects the best technically sound and cost effective solutions without any bias.

We strive to offer the best techno-commercial solutions as per client's specific applications and as per industry codes and standards, regulatory rules and guidelines.

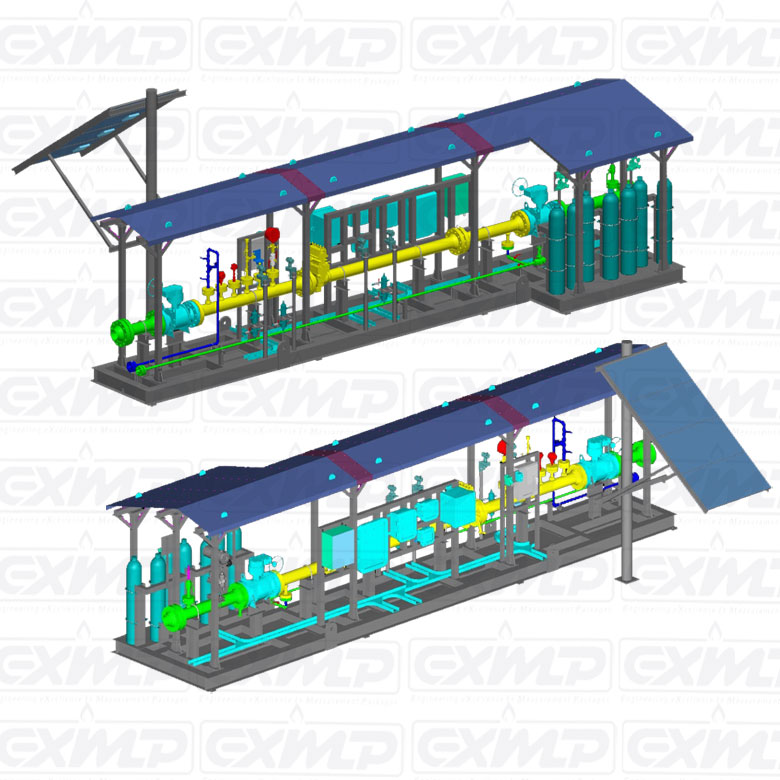

LIQUID AND GAS FLOW METERING SYSTEMS

EXIMP offers both liquid and gas flow metering systems with various types of flowmeters such as ultrasonic, turbine, Coriolis, DP meters etc. Our independent position lets us offer our customers optimized and process-fit metering packages.

FLEXIBILITY & OWNERSHIP

Our flow metering systems are skid mounted and fabricated in-house. This helps us offer flexibility and highest quality during project execution.

Our packages come with EXIMP's full system responsibility which includes:

- Electrical, mechanical and instrument engineering

- Fabrication assembly and testing

- Project management

- Flow computers

- Software programming

- Control panels

- Certification

- Integration with clients control system

- Installation commissioning and start-up assistance

- Training

INSTRUMENTATION AND FIELDBUS SOLUTIONS

EXIMP combines world-class products with unparalleled application expertise and industry knowledge. The current generation of Fieldbus-capable devices and systems from EXIMP provide true interoperability, allowing you the freedom to select the most appropriate devices and Fieldbus for your application. Our instrumentation product range includes transmitters, recorders, indicators, flow meters, analyzers and valves. Our Fieldbus offers guarantee safe, secure and reliable operations through their unique built-in redundancy.

A gas flow computer that incorporates a fully programmable PLC that can be used for process control, valve switching, pressure control and more.

A Modbus multivariable transmitter measures process temperature, process pressure and differential pressure and offers both Ethernet and Serial communications. Configurable through our software this transmitter includes a PID controller, analog output and LCD display.

Solar-powered, single run EFM has integrated Bluetooth ® wireless technology and radio communications for drive-up and remote connections. The multi-run gas flow computer software module can be used in the measurement of up to ten gas flow runs. This product converts any of the EXIMP controllers into a full function gas flow computer.

GAS ANALYSIS

EXIMP helps you maintain good standards of quality control. Our products include sampling systems and analyzers that measures pH, density, conductivity and turbidity.

We also offer gas chromatographs, mass spectrometers, FTIR spectrometers and photometers (IR and UV).

From high-quality portable field to stand alone measurement instruments and system EXIMP offers you end to end solutions that will help you monitor, protect and control your critical processes and applications.

Whether your process is up, mid or downstream, and application demands for custody transfer meters or accurate measurement of liquid or gas, EXIMP understands that an integrated equipment and expertise solution can help give you a competitive advantage. We are the experts for dependable and accurate flow measurement systems and will work with you to analyze your unique requirements and provide answers to your technical and business related problems.

INTEGRATED DESIGN CAPABILITIES

Our group of specialized measurement engineers consciously make the right engineering decisions and thus help positively impact the project costs and design. We are adept at selecting the right metering technology, making right engineering decisions, anticipating operations and installation to design problems, which helps us avoid costly changes during execution.

The basic requirement of any flow metering package is selecting the right measuring principle. This in turn depends on the selection and sizing of the flowmeter, service fluid properties, system uncertainty, flow rates, system pressure drop etc.