- Home

- Validation System

1. Gas Chromatograph Analysis Software (GCAS)

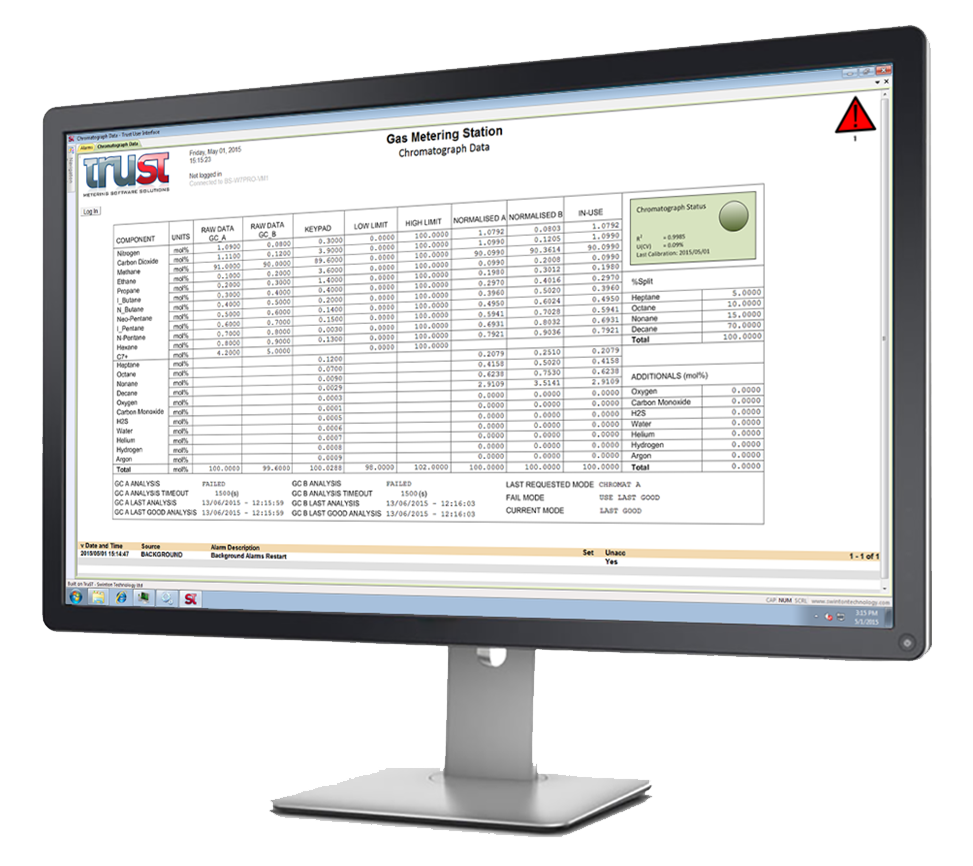

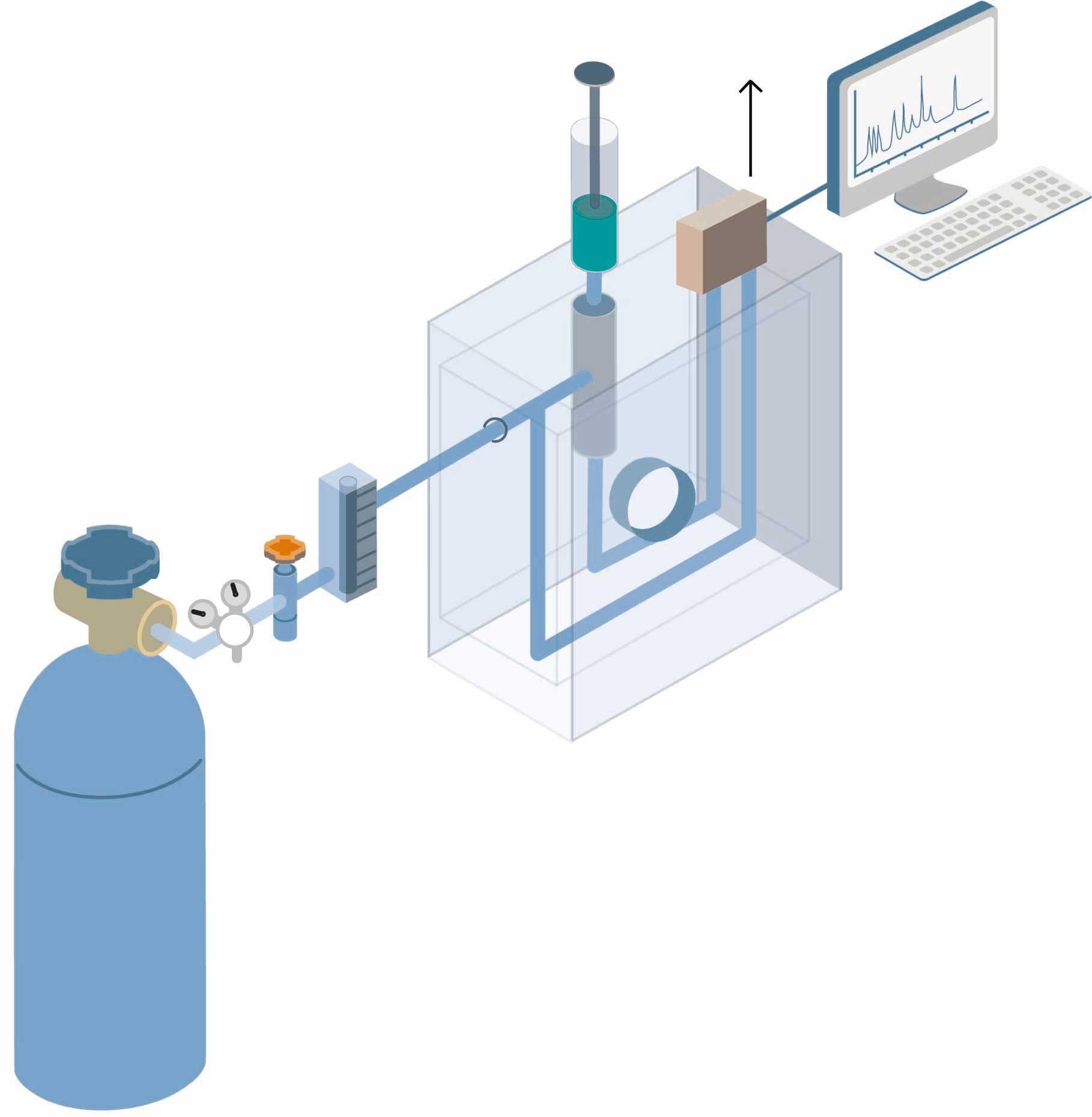

What is GCAS ?

A unique and comprehensive Condition Based Monitoring (CBM) software package for Gas Chromatograph (GCs), providing patented live uncertainty calculations based on routine gas calibrations.

As an automated condition based monitoring software GCAS:

- Provides real time assurance that the GC is operating correctly

- Analysis historical data to identify changes and predict future failures

- Reduces the need for conventional maintenance and unnecessary costs

- Determines dynamic GC uncertainty for quantification of GC performance

- Validates that the pressure let down system provides a representative sample

- Create a fully auditable database of GC performance

- Helps to support and increase a technician's competence level

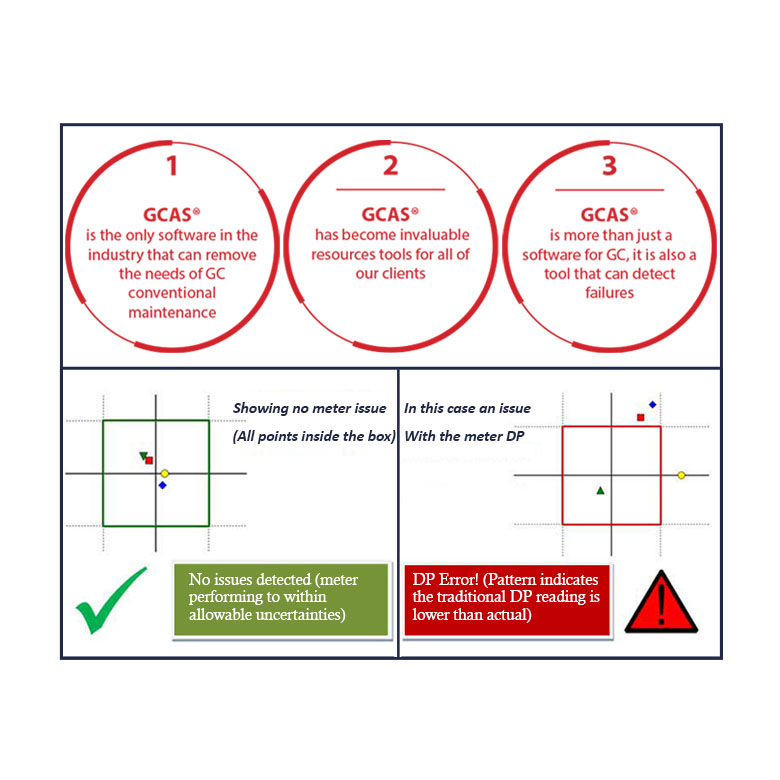

2. Prognosis

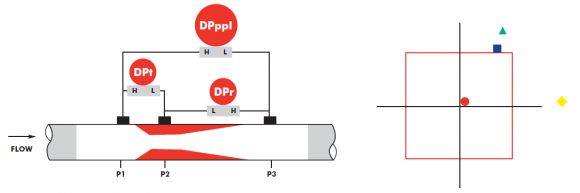

Prognosis is the only comprehensive DP meter diagnostic system available. Prognosis is capable of real-time diagnostics and is extremely powerful in assuring good flow measurement and detecting issues with any standard DP Meter. Prognosis can be used as a basis for a Condition Based Maintenance strategy as encouraged by regulatory bodies world-wide.

Prognosis is a DP meter diagnostic and Condition Based Monitoring (CBM) system, providing assurance of meter system accuracy and real time alerts to meter system malfunctions. Prognosis can be used as a basis for a Condition Based Maintenance strategy as encouraged by DECC.

Prognosis can considerably help in reducing maintenance costs, improving fault detection and detecting mismeasurements as soon as they occur.

The Prognosis User Interface is designed to be easy to use and intuitive. Prognosis can be run and displayed with no login required.